AMS Sugar II offers cutting-edge modules and services for the beverage industry. With modules like the Sugar Dissolver, Syrup Kitchen, Beverage Mixer, and Carbonator, AMS enhances production efficiency and maximizes flavor and quality. Additionally, their yeast propagation system optimizes beer production, while their services provide tailored solutions, seamless integration, operational support, and maintenance. Discover the benefits of AMS Sugar II, from increased efficiency and consumer satisfaction to sustainability goals and innovation in beverage production. Explore their capacity options and comprehensive product list for a competitive edge in the industry.

- The Importance of AMS Sugar II in the Beverage Industry

- Understanding the AMS Sugar II Modules

- Sugar Dissolver: Improving Sugar Dissolution Process

- Syrup Kitchen: Streamlining Beverage Production with Innovative Syrup Preparation

- Beverage Mixer: Creating Unique and Delicious Drink Combinations

- Beverage Degasser: Enhancing Beverage Shelf-life with Advanced Degassing

- Carbonator: Carbonating Beverages to Perfection

- AMS Sugar II Yeast Propagation for Brewery Operations

- AMS Sugar II Services for Efficient Production Management

- The Benefits of AMS Sugar II in the Beverage Industry

- Exploring AMS Sugar II Capacity Options and Product List

- AMS Sugar II: Innovation in Beverage Production and Management

- Ams sugar model

- Ams sugar model

The Importance of AMS Sugar II in the Beverage Industry

AMS Sugar II plays a crucial role in revolutionizing the beverage industry by providing cutting-edge modules and solutions. With an ever-growing demand for high-quality and innovative beverages, companies need to enhance their production efficiency and maximize flavor and quality to stay competitive. This is where AMS Sugar II comes in as a game-changer.

Enhancing Production Efficiency with AMS Sugar II Modules

AMS Sugar II offers a range of modules designed to streamline and optimize beverage production processes. The Sugar Dissolver module ensures efficient sugar dissolution, eliminating potential clumps and ensuring even distribution throughout the mixture. This results in consistent taste profiles and improved production efficiency.

The Syrup Kitchen module simplifies beverage production by providing innovative syrup preparation capabilities. With tanks for blending, syrup routing modules, container stations, and solid dissolving mixers, the Syrup Kitchen enables continuous syrup preparation while reducing oxygen content and pre-carbonating the syrup for enhanced quality.

The Beverage Mixer module facilitates the creation of unique and delicious drink combinations. With advanced mixing capabilities, it allows for precise blending of ingredients, ensuring consistency and enhancing flavor profiles. Whether it's creating new signature drinks or maintaining the consistency of existing recipes, the Beverage Mixer module delivers exceptional results.

The Beverage Degasser module extends the shelf life of beverages by removing excess gases that can degrade the quality and flavor. By gently degassing the beverages, AMS Sugar II ensures that they retain their desired characteristics, providing a longer shelf life and improved consumer satisfaction.

The Carbonator module excels in carbonating beverages to perfection, offering a range of carbonation options. Utilizing CO2 gas, AMS Sugar II achieves precise and customizable carbonation, enhancing the quality and taste of carbonated drinks such as sodas, juices, and beers.

Maximizing Flavor and Quality with AMS Sugar II Solutions

In addition to its modules, AMS Sugar II provides comprehensive solutions to maximize the flavor and quality of beverages. By utilizing AMS Sugar II, companies can achieve consistency and quality in their beer production through the dedicated yeast propagation system. This system optimizes yeast growth, ensuring optimal fermentation and the desired flavor profiles in each batch of beer.

Moreover, AMS Sugar II offers a range of services to support efficient production management. With engineering services, AMS Sugar II provides tailored solutions for beverage processing, ensuring seamless integration into existing production lines. Project implementation services guarantee a smooth transition, minimizing disruptions and maximizing efficiency. Operational support and maintenance services further ensure continuous operations, eliminating downtime and maintaining optimal performance.

In a competitive beverage industry, AMS Sugar II is instrumental in helping companies meet consumer demand for high-quality products. By increasing production efficiency, maximizing flavor and quality, and providing comprehensive support, AMS Sugar II empowers businesses to stay ahead of the curve and thrive in the ever-evolving market landscape.

Understanding the AMS Sugar II Modules

The AMS Sugar II modules play a crucial role in revolutionizing beverage production processes, offering enhanced efficiency and quality. Let's explore the different modules and their unique features:

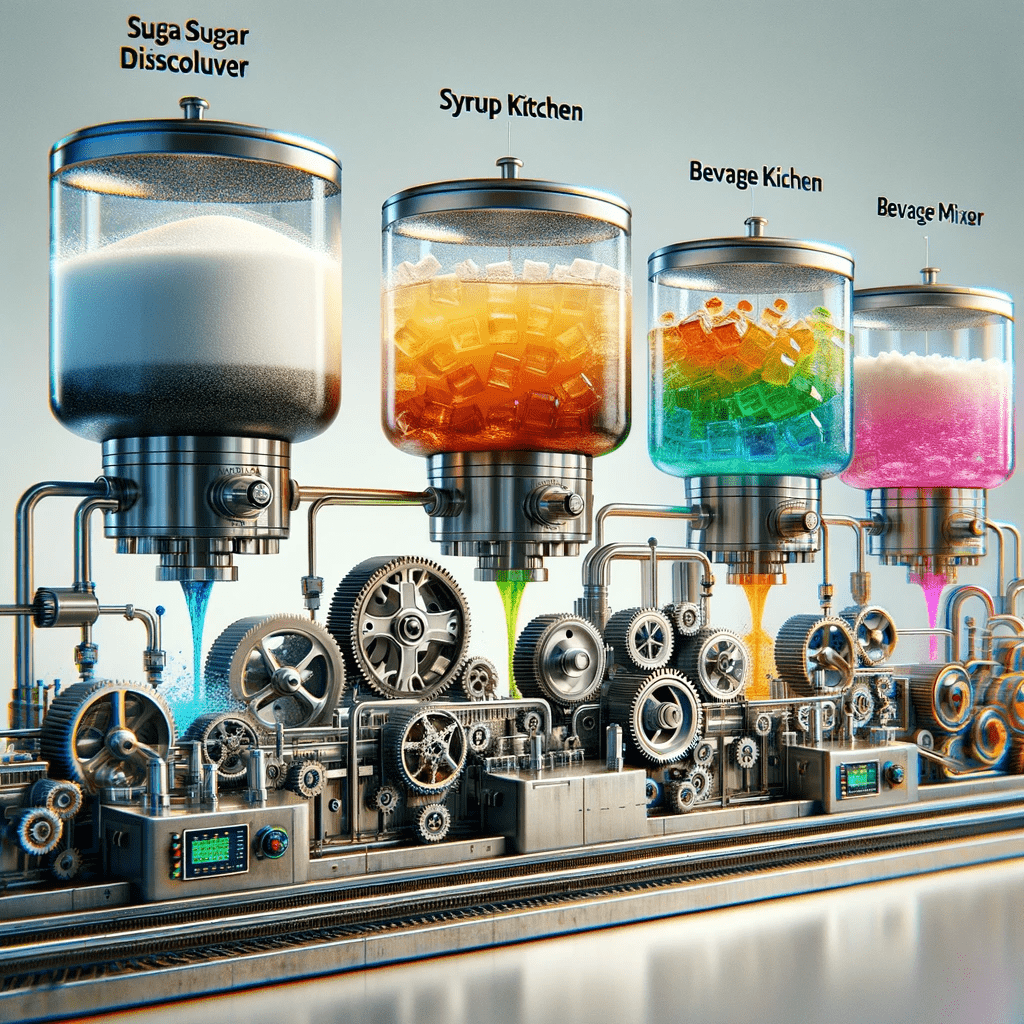

Sugar Dissolver: Improving Sugar Dissolution Process

The Sugar Dissolver module is designed to optimize the dissolution of sugar in beverage production. It utilizes advanced technology to ensure thorough and efficient sugar dispersion, resulting in a homogeneous mixture. This module greatly improves production consistency and reduces the risk of sugar clumping.

Syrup Kitchen: Streamlining Beverage Production with Innovative Syrup Preparation

The Syrup Kitchen module is a game-changer in beverage production. It consists of tanks, syrup routing modules, container stations, and mixing elements. This system enables continuous syrup preparation while decreasing oxygen content and pre-carbonating the syrup. The innovative design of the Syrup Kitchen module ensures efficient and consistent production of high-quality beverages.

Beverage Mixer: Creating Unique and Delicious Drink Combinations

The Beverage Mixer module offers endless possibilities for beverage creation. It combines different flavors and ingredients to create unique and delicious drink combinations. With precise control over mixing ratios, this module enables beverage manufacturers to meet the ever-changing demands of consumers seeking innovative and exciting flavors.

Beverage Degasser: Enhancing Beverage Shelf-life with Advanced Degassing

The Beverage Degasser module plays a crucial role in improving the shelf-life of beverages. It effectively removes dissolved gases, such as oxygen, from the liquid, ensuring longer freshness and preventing flavor deterioration. By using advanced degassing techniques, this module helps beverage manufacturers maintain the desired quality and taste of their products over time.

Carbonator: Carbonating Beverages to Perfection

The Carbonator module is an essential component for carbonating beverages to perfection. It utilizes CO2 gas to achieve precise and consistent carbonation levels, ensuring a refreshing and enjoyable drinking experience. With the ability to carbonate beverages up to 10g per liter of CO2, this module allows beverage producers to meet the specific carbonation preferences of their customers.

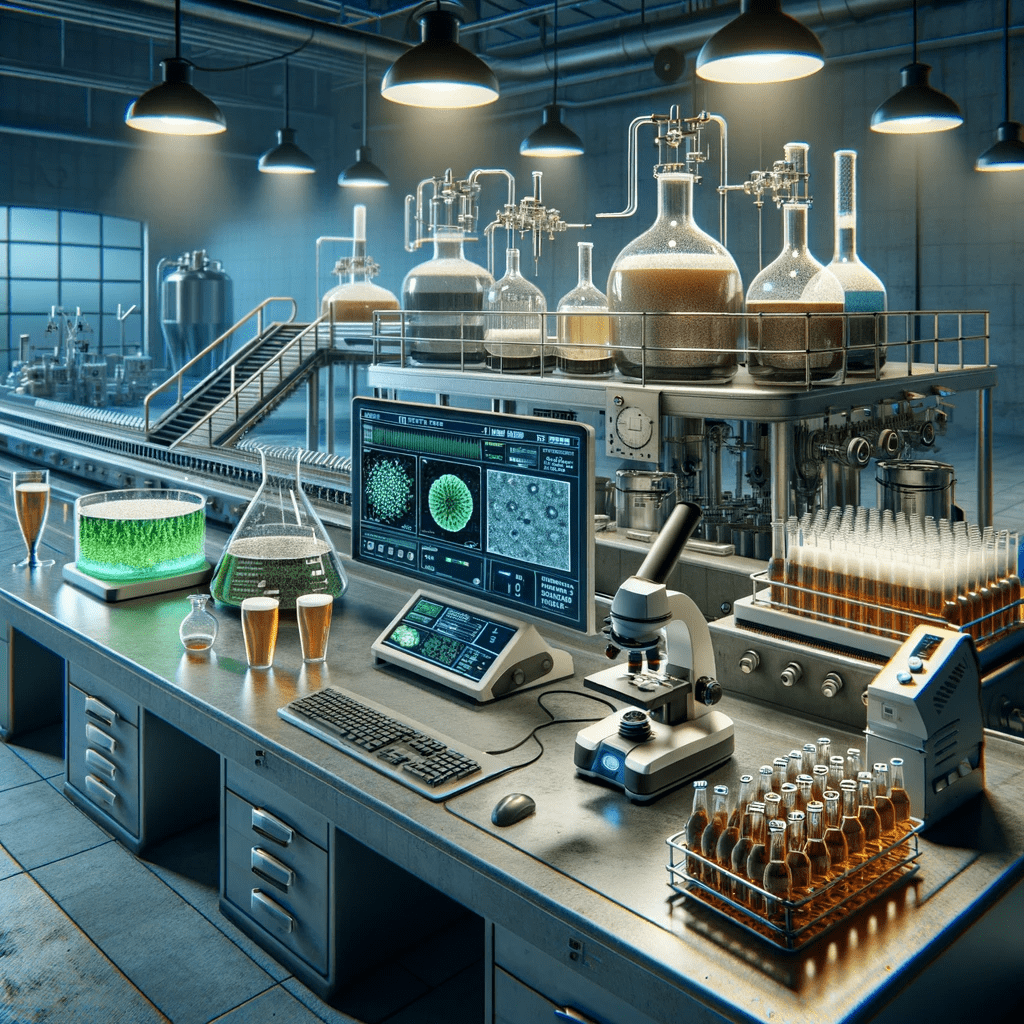

AMS Sugar II Yeast Propagation for Brewery Operations

Discover the power of AMS Sugar II yeast propagation system in optimizing beer production and ensuring consistency and quality. With AMS Sugar II, breweries can take their brewing process to the next level by efficiently propagating yeast and achieving desired flavor profiles.

Yeast Propagation: Optimizing Beer Production

The yeast propagation module offered by AMS Sugar II revolutionizes the brewing industry by streamlining the yeast reproduction process. This advanced system allows breweries to produce a higher quantity of high-quality yeast for fermentation, resulting in improved beer consistency and flavor.

By controlling key parameters such as temperature, nutrient levels, and pH, AMS Sugar II ensures the ideal conditions for yeast growth and propagation. This optimization greatly reduces the risk of off-flavors and improves the overall fermentation process, ultimately leading to exceptional beer quality.

Achieving Consistency and Quality with AMS Sugar II Yeast Propagation

Consistency is a vital aspect of any successful brewery, and AMS Sugar II yeast propagation system provides the tools to achieve it. With precise control over yeast reproduction, breweries can maintain a consistent yeast strain throughout production, resulting in consistent flavor profiles across batches.

AMS Sugar II's yeast propagation system also enhances the quality of beer by ensuring the purity and vitality of the yeast culture. By eliminating contamination risks and maintaining optimal yeast health, breweries can produce beer with superior taste, clarity, and aroma.

The AMS Sugar II yeast propagation system is a game-changer for breweries, enabling them to produce high-quality, consistent beer while maximizing production efficiency. With AMS Sugar II, brewers can craft exceptional brews that delight their customers and set them apart in the competitive beer industry.

AMS Sugar II Services for Efficient Production Management

Engineering Services: Tailored Solutions for Beverage Processing

AMS Sugar II offers comprehensive engineering services to provide tailored solutions for beverage processing. Our team of expert engineers works closely with clients to understand their specific needs and design efficient systems that optimize production processes. From initial concept development to the final implementation, our engineering services ensure seamless integration of AMS Sugar II modules and technologies into existing production setups. We prioritize quality, reliability, and cost-effectiveness to deliver innovative solutions that enhance productivity and meet the unique requirements of each client.

Project Implementation: Seamless Integration of AMS Sugar II Systems

At AMS Sugar II, we understand the importance of smooth project implementation. Our dedicated team works closely with clients to ensure seamless integration of AMS Sugar II systems into their production facilities. We offer comprehensive project management, including planning, coordination, and monitoring, to ensure projects are delivered on time and within budget. Our experienced technicians provide installation, setup, and testing services to guarantee proper functionality and optimal performance of the AMS Sugar II modules. With our commitment to excellence, we strive to exceed client expectations and deliver exceptional project implementation services.

Operational Support: Ensuring Smooth Production Operations

AMS Sugar II is committed to ensuring smooth production operations for our clients. We provide comprehensive operational support to address any challenges that may arise during beverage production. Our technical experts are available round the clock to provide assistance, troubleshoot issues, and optimize the performance of AMS Sugar II modules. We offer training programs to empower production teams with the knowledge and skills necessary to operate and maintain the AMS Sugar II systems effectively. With our operational support, clients can minimize downtime, maximize productivity, and achieve consistently high-quality beverage production.

Maintenance Services: Maximizing Longevity and Performance

Maintenance is crucial for maximizing the longevity and performance of AMS Sugar II systems. We offer comprehensive maintenance services to ensure the seamless operation of our modules. Our team of skilled technicians conducts regular inspections, preventive maintenance tasks, and repairs to identify and address any potential issues before they impact production. We provide prompt response times and efficient service to minimize downtime and optimize system performance. With our maintenance services, clients can rely on AMS Sugar II to deliver long-lasting, reliable, and efficient beverage production solutions.

The Benefits of AMS Sugar II in the Beverage Industry

AMS Sugar II offers numerous advantages for businesses operating in the beverage industry. From increased efficiency and cost savings to meeting consumer demands for high-quality products and achieving sustainability goals, AMS Sugar II provides a comprehensive solution for beverage production.

Increased Efficiency and Cost Savings with AMS Sugar II

By implementing AMS Sugar II modules and services, companies can significantly enhance their production processes, leading to improved efficiency and cost savings. The advanced technology and innovative solutions offered by AMS Sugar II streamline operations, reduce manual labor, minimize waste, and optimize resource utilization. This results in enhanced productivity, reduced production costs, and increased profitability.

Meeting Consumer Demand for High-Quality Products

Consumer preferences are continually evolving, with a growing emphasis on high-quality beverages. AMS Sugar II enables businesses to meet these evolving demands by providing modules designed to enhance flavor and quality. The Sugar Dissolver, Syrup Kitchen, Beverage Mixer, Beverage Degasser, and Carbonator offered by AMS Sugar II ensure that beverages are consistently delicious, well-mixed, degassed, and appropriately carbonated. This focus on product quality helps businesses maintain a competitive edge and satisfy their customers' taste preferences.

Achieving Sustainability Goals with Lower Energy Consumption

In today's environmentally conscious world, sustainability is a top priority for many businesses. AMS Sugar II aids in achieving sustainability goals by promoting lower energy consumption. The modules and systems provided by AMS Sugar II are designed with energy-efficient features and optimized processes, minimizing the overall environmental footprint of beverage production. This commitment to sustainability benefits both the business and the planet, reducing energy costs while supporting sustainable practices.

Exploring AMS Sugar II Capacity Options and Product List

AMS Sugar II Capacity Range for Various Production Needs

AMS Sugar II offers a diverse range of capacity options to meet the varying production needs of beverage manufacturers. With their innovative modules and solutions, AMS Sugar II can accommodate small-scale operations, as well as large-scale production facilities. Whether you're a startup looking to expand or an established company seeking to optimize your production capacity, AMS Sugar II has the right solution for you.

From compact setups for low-volume production to high-capacity systems for large-scale operations, AMS Sugar II provides flexibility in meeting your specific production requirements. Their capacity range includes options suitable for small craft breweries, as well as high-volume beverage manufacturers. With AMS Sugar II, you can scale your production capacity according to market demand and ensure efficient and consistent beverage production.

Comprehensive List of AMS Sugar II Products

AMS Sugar II offers an extensive list of products designed to enhance beverage production and processing. Their comprehensive range of modules ensures efficient and high-quality operation across various stages of the production process.

- Sugar Dissolver: Efficiently dissolves sugar for smooth beverage preparation.

- Syrup Kitchen: Streamlines syrup production with advanced mixing and pre-carbonation capabilities.

- Beverage Mixer: Creates unique and delicious drink combinations with precision.

- Beverage Degasser: Enhances beverage shelf-life through advanced degassing techniques.

- Carbonator: Perfectly carbonates beverages, ensuring optimal taste and effervescence.

These are just a few examples of the innovative products offered by AMS Sugar II. Their product list goes beyond these modules to include various other solutions tailored to meet specific production needs and requirements. With AMS Sugar II, beverage manufacturers can achieve superior product quality, efficient production processes, and enhanced customer satisfaction.

AMS Sugar II: Innovation in Beverage Production and Management

As the beverage industry becomes increasingly competitive, staying ahead requires embracing innovation and leveraging cutting-edge solutions. AMS Sugar II offers a range of modules and services that revolutionize beverage production and management.

Staying Ahead in the Competitive Industry with AMS Sugar II

With the rapidly evolving preferences of consumers, it is crucial for beverage companies to continuously innovate and adapt. AMS Sugar II provides the tools and technology to create unique and delicious drink combinations, enhance product quality, and streamline production processes.

- Enhancing Production Efficiency with AMS Sugar II Modules: Utilize the Sugar Dissolver, Syrup Kitchen, Beverage Mixer, and Beverage Degasser modules to optimize production efficiency and reduce costs. These modules are designed to dissolve sugar, prepare innovative syrups, create customized drink combinations, and extend shelf-life through advanced degassing.

- AMS Sugar II: Precise, consistent flavors; maintains highest quality. Carbonator module perfects beverage carbonation. Flash Pasteurizer ensures safety, extends shelf-life, maintains taste.

The Role of AMS Sugar II in Beverage Industry Process Enhancement

AMS Sugar II plays a vital role in enhancing beverage production processes and management. By leveraging AMS Sugar II modules and services, companies can achieve greater operational efficiency, cost savings, and customer satisfaction.

- Engineering Services: AMS offers tailored engineering solutions to optimize beverage processing, ensuring seamless integration of AMS Sugar II systems.

- Project Implementation: AMS Sugar II facilitates the smooth implementation of projects, minimizing disruptions to production operations.

- Operational Support: AMS Sugar II provides ongoing support to ensure the efficient and smooth running of beverage production operations.

- Maintenance Services: AMS Sugar II offers comprehensive maintenance services to maximize longevity and performance, reducing downtime and production losses.

With AMS Sugar II, companies can overcome industry challenges, meet consumer demands for high-quality beverages, and achieve their sustainability goals. Embrace innovation and elevate your beverage production and management with AMS Sugar II.

Ams sugar model

In the realm of agricultural machinery, the AMS Sugar II stands out as a beacon of innovation, designed to streamline sugar production at every phase. This advanced model synthesizes cutting-edge technology with user-friendly features, offering an unparalleled solution for sugar cane processors. The AMS Sugar II isn't just a machine; it's a comprehensive system that promises to enhance yield, reduce waste, and optimize the entire production line.

- High-Efficiency Milling: Enhanced roller technology for maximum juice extraction.

- Energy-Saving Operations: State-of-the-art motors that reduce power consumption.

- Automated Control Systems: Intuitive interfaces for precise process management.

- Durable Construction: Robust materials and design for extended lifespan under harsh conditions.

- Smart Monitoring: Real-time data tracking for proactive maintenance and optimization.

- Flexibility in Processing: Versatile components adaptable to various sugar cane types and conditions.

- Eco-Friendly Design: Solutions that minimize environmental impact while maintaining high productivity.

Ams sugar model

In the dynamic world of agricultural machinery, the AMS Sugar II stands as a testament to innovation and efficiency in sugar production. This advanced model is tailored to meet the high demands of modern agriculture, offering an array of innovative modules designed to enhance productivity and optimize sugar processing. From precision planting to efficient harvesting, the AMS Sugar II integrates cutting-edge technology to ensure that every phase of sugar production is executed with excellence. Below is a list of key elements that embody the essence of the AMS Sugar II model:

- High-Performance Cutting System: Ensures clean and precise cuts for optimal plant growth and sugar yield.

- Automated Planting Solutions: Offers uniform planting depth and spacing, leading to improved crop establishment.

- Integrated Pest Management: Utilizes advanced sensors to detect and manage pests, safeguarding crops with minimal environmental impact.

- Real-Time Data Analysis: Employs sophisticated software to monitor and analyze crop health and soil conditions, enabling informed decision-making.

- Energy-Efficient Operations: Designed to reduce fuel consumption and emissions, promoting sustainable agricultural practices.

- Customizable Attachments: Features a range of attachments that can be tailored to specific farming needs, enhancing the versatility of the AMS Sugar II.

- Rugged Durability: Built to withstand the harsh conditions of sugar cane fields, ensuring reliability and a long service life.

- Advanced Harvesting Technology: Streamlines the harvesting process, reducing waste and increasing the speed of production.